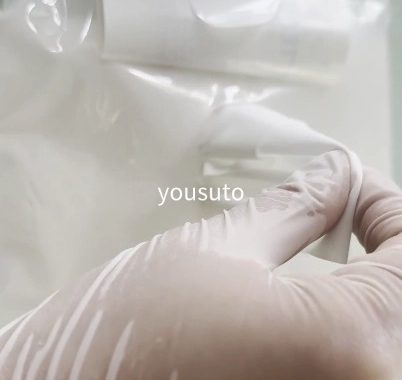

Antistatic cleanroom wipes are essential in semiconductor production, where even tiny particles or electrostatic discharges (ESD) can damage delicate components and reduce yield. These wipes ensure cleanliness, safety, and efficiency throughout the manufacturing process.

Key Features:

-

Antistatic Protection: Prevents electrostatic discharge, protecting sensitive semiconductors, wafers, and electronic components from ESD-related failures.

-

Lint-Free and Non-Abrasive: Ensures no fiber shedding or scratches, maintaining the integrity of delicate surfaces.

-

High Absorbency: Captures dust, oils, and residues effectively, reducing contamination risk on critical components.

-

Chemical Resistance: Compatible with solvents like IPA, deionized water, and other cleaning agents used in semiconductor manufacturing.

Applications:

-

Wafer Handling: Maintains particle-free surfaces during wafer processing and inspection.

-

PCB Cleaning: Removes dust, oils, and residues from printed circuit boards without causing damage.

-

Semiconductor Assembly: Protects microchips and delicate components during assembly and testing.

-

Cleanroom Maintenance: Ensures Class 100 or higher cleanroom surfaces remain contaminant-free.

Benefits:

-

Reduces ESD Risks: Protects high-value components from static-related failures.

-

Maintains Cleanliness Standards: Lint-free and absorbent wipes prevent particle contamination.

-

Enhances Production Yield: Cleaner surfaces and controlled ESD lead to higher reliability and quality.