Isopropyl alcohol (IPA) wipes are a widely used solution for cleaning precision equipment, offering effective removal of dust, oils, and residues. However, their use requires careful handling to prevent damage to sensitive components and ensure optimal cleaning results.

Key Features:

-

High Purity IPA: IPA wipes are typically soaked in high-purity isopropyl alcohol, ensuring effective cleaning without leaving harmful residues.

-

Lint-Free: Designed to be lint-free, these wipes prevent fibers from contaminating sensitive equipment.

-

Quick Drying: IPA evaporates rapidly, leaving no moisture behind, which is essential for cleaning delicate surfaces.

-

Antistatic Properties: Many IPA wipes are treated with antistatic properties, reducing the risk of electrostatic discharge (ESD) during cleaning.

Precautions:

-

Avoid Excessive IPA Use: Too much IPA on a wipe can lead to excessive moisture, which could damage sensitive equipment. Always ensure the wipe is damp, not wet.

-

Test on Small Area First: Before using IPA wipes on sensitive or delicate surfaces, always test them on a small, inconspicuous area to ensure compatibility.

-

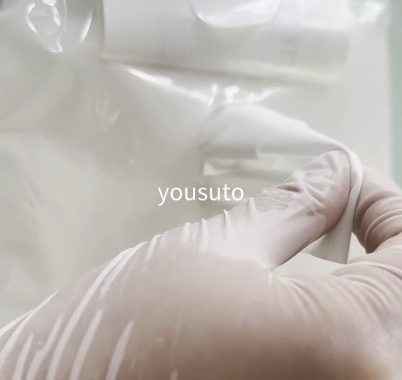

Handle with Care: Always use gloves or clean tools to handle the wipes, avoiding direct contact that could introduce contamination.

-

Proper Storage: Store IPA wipes in sealed, contamination-free environments to preserve their cleanliness and prevent IPA evaporation.

-

Single Use Only: For optimal results, use the wipe once and dispose of it immediately to avoid cross-contamination.

Application Range:

-

Precision Instruments: Ideal for cleaning microscopes, measurement devices, and other precision tools.

-

Medical Devices: Used to clean delicate medical instruments without damaging them or affecting their function.

-

Laboratory Equipment: Ensures laboratory instruments remain free of dust and residues, maintaining accuracy in experiments.

-

Electronics: Used for cleaning circuit boards, displays, and other electronic components to maintain performance and reliability.

Best Practices:

-

Use in Controlled Environments: Always use IPA wipes in controlled environments like cleanrooms to maintain sterility and cleanliness.

-

Wipe in One Direction: Wipe surfaces in a single direction to ensure complete removal of contaminants without reintroducing particles.