In industries such as pharmaceutical manufacturing, semiconductors, and precision optics—where cleanroom requirements are stringent—the choice of gloves not only protects operators but also directly impacts product quality and compliance. RotAdler Pharma gloves, designed specifically for high-standard environments, offer outstanding cleanliness, chemical resistance, and comfort, making them ideal for various critical cleanroom applications.

I. Cleanroom Grades Suitable for RotAdler Pharma Gloves

RotAdler Pharma gloves are manufactured under strict cleanroom processes to ensure low particle generation, minimal extractables, and low volatile residues. They are suitable for:

-

ISO Class 5–7 cleanrooms (equivalent to Class 100–10,000)

-

GMP Grade A/B/C zones, ideal for sterile manufacturing, bioreactor handling, and vaccine filling

-

EU GMP Annex 1 compliant environments, especially sterile areas in European pharmaceutical production

-

PIC/S-compliant facilities, including global CDMOs and export-oriented pharmaceutical plants

II. Key Application Industries and Scenarios

1. Biopharmaceutical and Sterile Drug Manufacturing

For sterile processes such as cell culture, aseptic filling, and filtration, RotAdler Pharma gloves provide powder-free surfaces and excellent barrier protection, reducing the risk of cross-contamination.

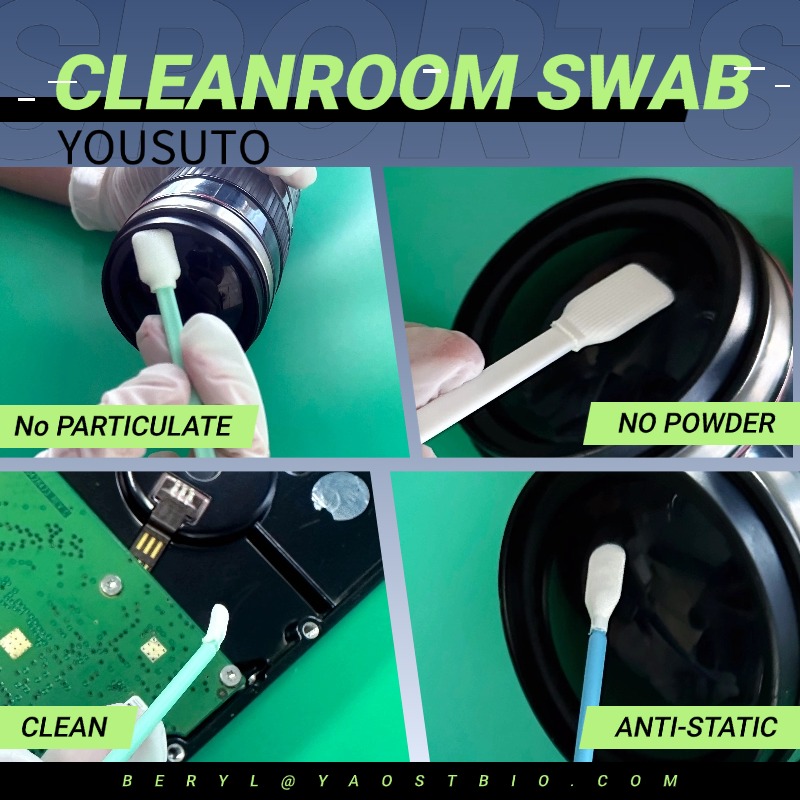

2. Semiconductor and Electronics Cleanrooms

In wafer handling, photolithography, and final assembly—where particles are critical—RotAdler Pharma gloves excel in electrostatic control and particulate suppression.

3. Medical Device Manufacturing and Assembly

Used in the production and inspection of implantable devices and precision catheters, these gloves minimize particulate contamination and ensure high-level cleanliness.

4. Aseptic Laboratories and Research Facilities

For applications like PCR, microbiology, and cell research, RotAdler Pharma gloves reduce contamination risk and ensure data integrity.

III. Key Product Features

-

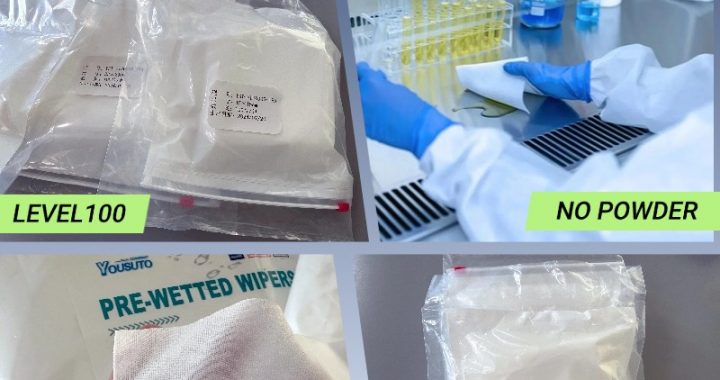

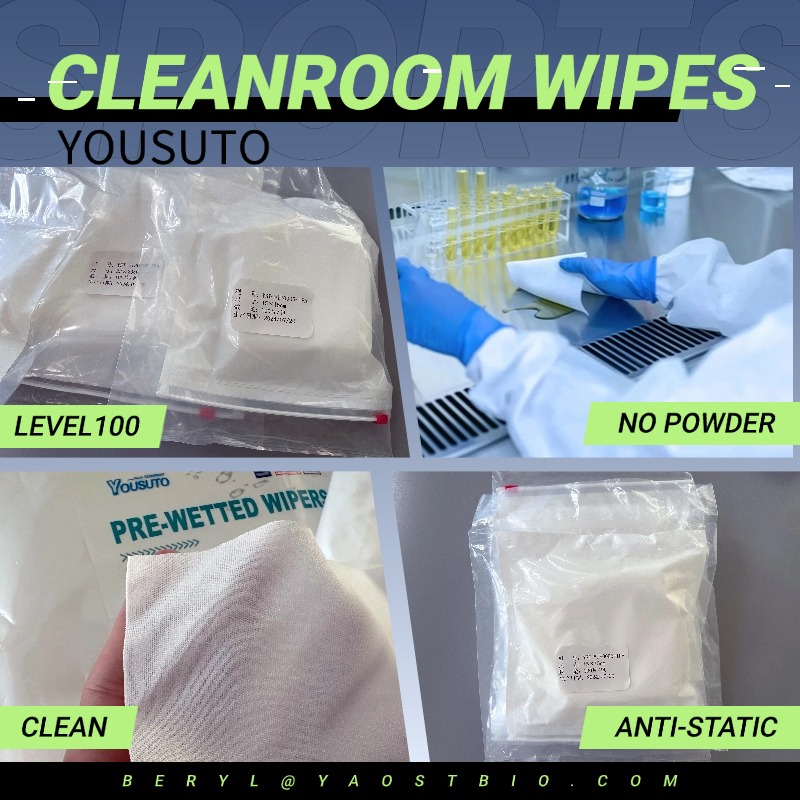

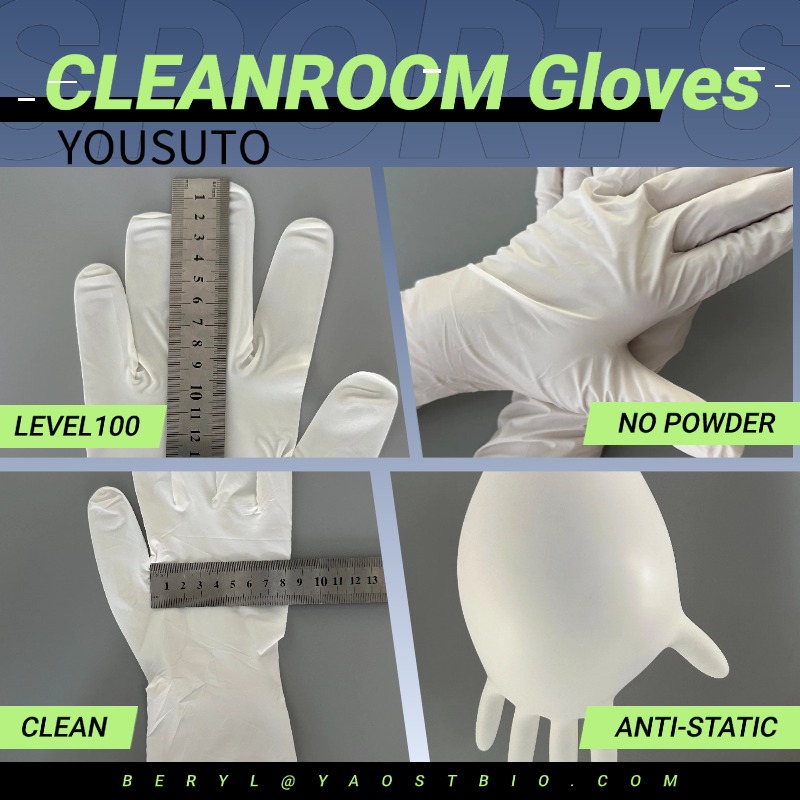

Powder-free design: Prevents allergic reactions and particulate contamination

-

Low-linting and low particle generation: Suitable for Class 100 cleanroom environments

-

High flexibility and puncture resistance: Ensures comfort during prolonged or detailed operations

-

Excellent chemical resistance: Compatible with disinfectants and cleaning agents

-

Certified to international standards: Complies with EN 374, ASTM D6319, ISO 13485, and more

IV. Why Choose RotAdler Pharma?

Compared to conventional medical or industrial gloves, RotAdler Pharma gloves are engineered to meet higher standards of cleanliness, safety, and compliance. They are ideal for environments that demand tight contamination control, regulatory assurance, and consistent batch quality—making them a smart investment for modern cleanroom operations.

Conclusion

In critical cleanroom environments, even the smallest detail can influence product safety and performance. RotAdler Pharma gloves, with their cleanroom-grade engineering and high-performance materials, offer dependable protection while ensuring compliance and reliability. For companies that demand the highest levels of contamination control, RotAdler is the professional choice.