Antistatic cleanroom wipes are essential for safeguarding electronic components in sensitive manufacturing and laboratory environments. They prevent electrostatic discharge (ESD) while effectively removing dust, oils, and other contaminants that could damage delicate electronics.

Key Features:

-

Antistatic Properties: These wipes dissipate static charges, preventing ESD that can damage sensitive components such as semiconductors, circuit boards, and microchips.

-

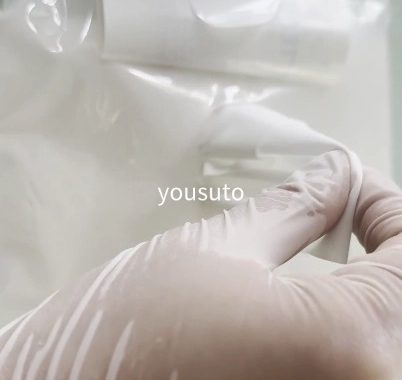

Lint-Free and Non-Abrasive: Designed to avoid leaving fibers or particles on surfaces, they ensure delicate electronics remain clean without scratches or residues.

-

High Absorbency: Efficiently captures oils, dust, and moisture, maintaining a contaminant-free environment for electronic parts.

-

Chemical Resistance: Compatible with cleaning solvents like isopropyl alcohol (IPA) and other non-corrosive agents, allowing safe cleaning without damaging components.

Applications:

-

Semiconductor Manufacturing: Protects wafers, chips, and circuit boards from static damage and contamination.

-

Electronics Assembly: Ensures components are free from dust and oils during production and handling.

-

Laboratories and Test Equipment: Maintains clean surfaces on sensitive measurement devices and testing instruments.

-

Optoelectronic Devices: Ideal for cleaning sensors, lenses, and other precision electronic parts.

Benefits:

-

Prevents ESD Damage: Safeguards electronic components from harmful static discharge, extending device lifespan.

-

Maintains Cleanliness: Lint-free and absorbent properties reduce contamination risk.

-

Enhances Reliability: Ensures components perform reliably by keeping them free from debris and static.