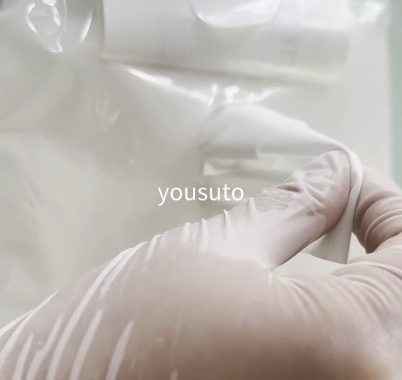

Cleaning wipes are essential tools for maintaining clean, safe, and efficient work environments. Proper usage of cleaning wipes can significantly enhance cleaning efficiency, reducing time and effort while ensuring thorough and effective surface cleaning. Here’s a guide to improving cleaning efficiency with the right techniques.

Key Features:

-

High Absorbency: Cleaning wipes are designed to absorb dust, oils, liquids, and residues quickly, making them ideal for efficient cleaning.

-

Lint-Free: These wipes leave no fibers behind, preventing contamination and ensuring a streak-free clean.

-

Durability: High-quality cleaning wipes are strong and resistant to tearing, even when used on rough or textured surfaces.

-

Antistatic Properties: Some wipes feature antistatic properties, which help reduce electrostatic discharge (ESD) during cleaning, especially important in sensitive environments.

Operational Tips:

-

Use the Right Wipe for the Job: Select the appropriate wipe for your cleaning task. For example, use high-absorbency wipes for liquid spills and lint-free wipes for precision cleaning in electronics or laboratory settings.

-

Single Use for Optimal Efficiency: Avoid reusing wipes as it can spread contaminants. Dispose of them after each use to maintain a clean environment.

-

Wipe in One Direction: To prevent reintroducing contaminants, always wipe in one direction rather than rubbing back and forth.

-

Proper Storage: Store cleaning wipes in sealed containers to avoid exposure to dust or moisture, which can affect their effectiveness.

-

Avoid Over-Saturating: Ensure the wipes are damp, not soaked. Over-saturation can leave residue on surfaces, affecting the cleaning process and causing longer drying times.

Application Range:

-

Electronics: Ideal for cleaning circuit boards, screens, and other sensitive components without damaging them.

-

Cleanrooms: Essential for wiping down work surfaces, equipment, and tools in controlled environments where contamination must be minimized.

-

Healthcare: Used for cleaning medical instruments, workstations, and surfaces to maintain hygiene and prevent cross-contamination.

-

General Maintenance: Useful for cleaning office spaces, floors, and other high-traffic areas, improving overall cleanliness.

Best Practices:

-

Store Properly: Keep wipes in a clean, dry environment to preserve their quality and effectiveness.

-

Use as Part of a Routine: Regular use of cleaning wipes as part of a maintenance routine helps ensure ongoing cleanliness and prevents build-up of contaminants.