Isopropyl alcohol (IPA) wipes are widely used for cleaning in various industries, particularly for removing dust, oils, and residues from sensitive surfaces. To maximize their effectiveness while ensuring safety and preserving the integrity of the surfaces, it’s crucial to follow the correct usage methods.

Key Features:

-

High Purity: IPA wipes typically contain 70% isopropyl alcohol, which effectively dissolves oils, dirt, and residues without leaving harmful residues behind.

-

Quick Drying: The alcohol evaporates quickly, leaving no moisture behind, making IPA wipes ideal for use on electronic and precision equipment.

-

Lint-Free: IPA wipes are designed to be lint-free, ensuring that no fibers or particles are left behind during cleaning.

-

Antistatic Properties: Many IPA wipes are treated to reduce electrostatic discharge (ESD), protecting sensitive electronic components from static damage.

Correct Usage:

-

Ensure Surface Compatibility: Test IPA wipes on a small, inconspicuous area before using them on sensitive surfaces to ensure there is no damage or discoloration.

-

Wipe in One Direction: For optimal cleaning, wipe in a single direction to avoid reintroducing contaminants. Use long, smooth strokes.

-

Avoid Overuse: Do not oversaturate the wipe. Excess liquid can cause damage to electronic components or create excess moisture on surfaces.

-

Use in Well-Ventilated Areas: IPA is flammable and may produce fumes. Always use IPA wipes in well-ventilated environments to avoid inhalation risks.

-

Single Use Only: Use each IPA wipe once and dispose of it immediately after use to prevent cross-contamination.

Application Range:

-

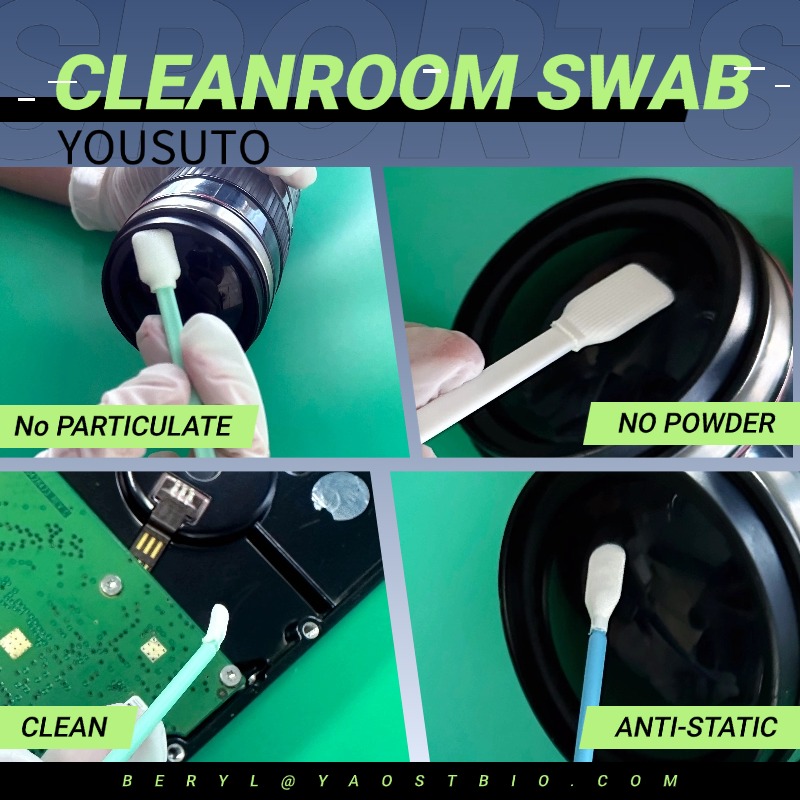

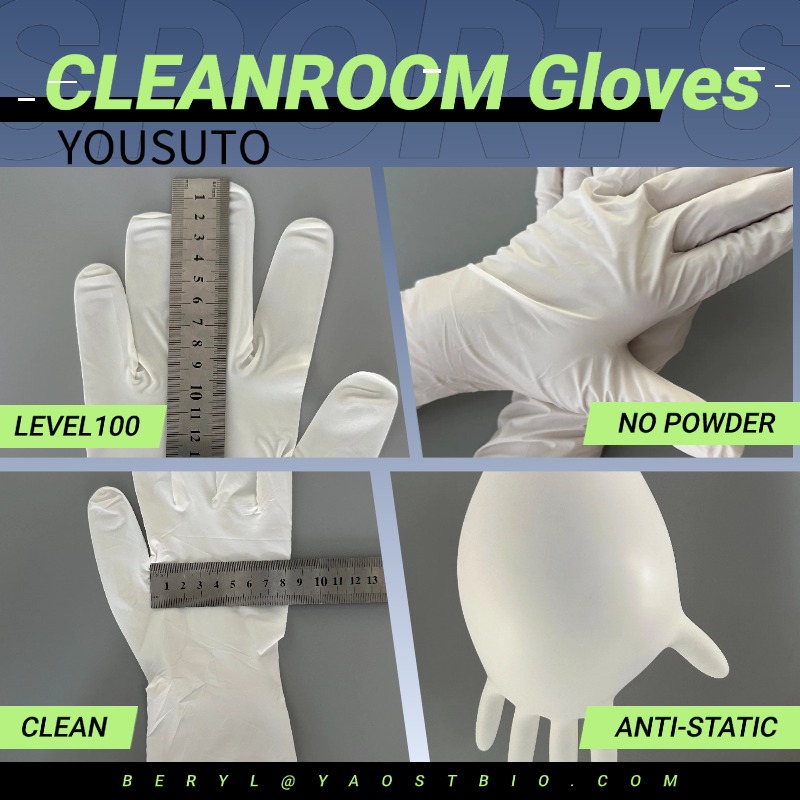

Electronics: Ideal for cleaning circuit boards, displays, and electronic components to prevent dust buildup and static discharge.

-

Optical Equipment: Used to clean lenses and optical instruments without leaving streaks or residue.

-

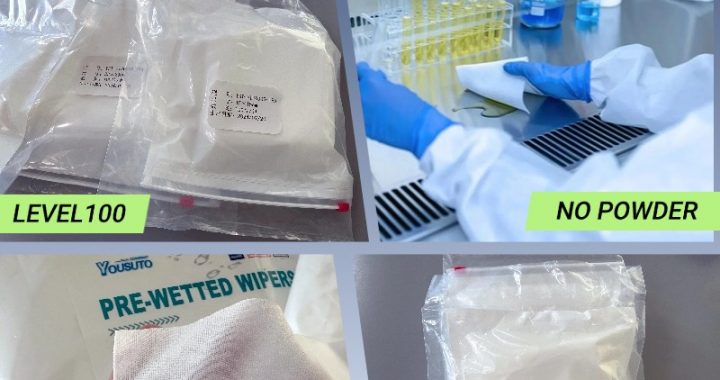

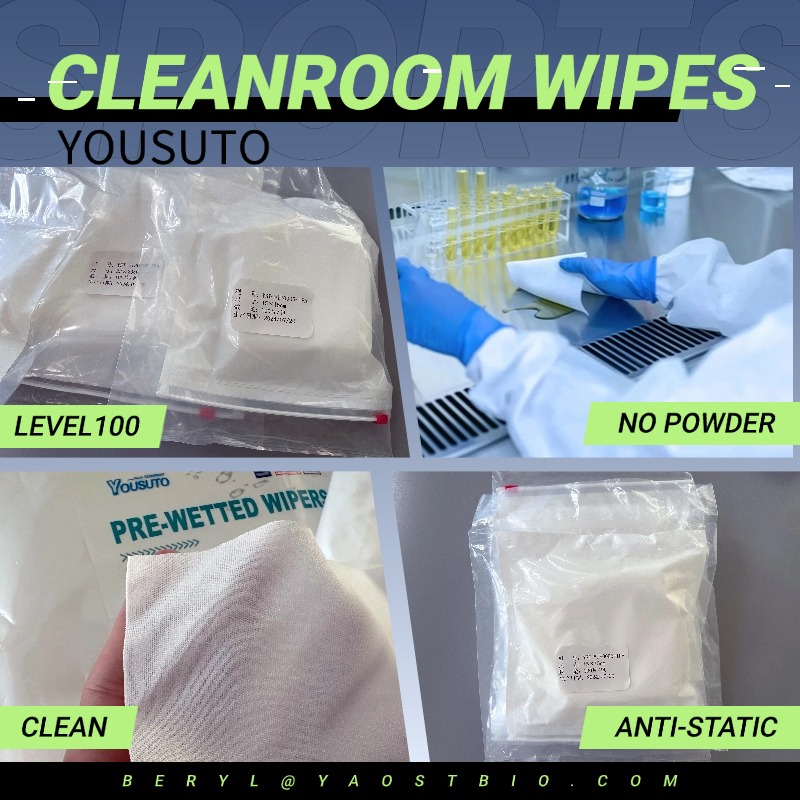

Laboratories: Used for cleaning lab surfaces, tools, and instruments to maintain cleanliness and prevent cross-contamination.

-

Medical Devices: IPA wipes help to clean medical tools and devices, ensuring they remain sterile and free of contaminants.

Best Practices:

-

Proper Storage: Store IPA wipes in sealed, contamination-free packaging to avoid evaporation and loss of cleaning efficacy.

-

Handle with Care: When cleaning sensitive equipment, ensure minimal contact with the wipe surface to maintain sterility and avoid cross-contamination.

干抹布.jpg)