Industrial Wipes

Overview:

Industrial Wipes are specialized cleaning products designed for heavy-duty use in industrial environments. They are engineered to handle a wide range of tough cleaning tasks, from wiping down machinery and equipment to cleaning workstations, tools, and surfaces in factories, warehouses, and production lines. Made from durable materials and designed for high absorbency, industrial wipes can effectively remove oils, grease, dust, dirt, chemicals, and other contaminants, ensuring a clean and safe work environment. Whether in manufacturing, construction, automotive, or electronics, these wipes help maintain equipment performance and workplace hygiene.

Product Features:

- Heavy-Duty Cleaning Power: Industrial wipes are made to handle the toughest cleaning challenges, including the removal of grease, oils, lubricants, solvents, dust, and general dirt. They are built for industrial-grade cleaning and offer exceptional performance even in demanding environments.

- Highly Absorbent: These wipes have superior absorbency, making them ideal for soaking up spills, wiping down large surfaces, and removing excess oils or chemicals without leaving residues behind. This helps reduce waste and increases cleaning efficiency.

- Durable and Tear-Resistant: Industrial wipes are designed to be durable and tough, withstanding abrasion and friction during use. They are resistant to tearing, ensuring they remain effective for multiple cleaning tasks without falling apart.

- Non-Linting and Low Residue: Many industrial wipes are specifically engineered to be non-linting, meaning they won’t leave fibers or debris behind when wiping surfaces. This is particularly important in sensitive areas, such as electronics or cleanrooms, where lint or residue can cause damage.

- Chemical-Resistant: Industrial wipes are often resistant to a wide range of solvents, chemicals, and cleaning agents, making them suitable for use in environments where harsh substances are common, such as automotive workshops, manufacturing plants, and laboratories.

- Multi-Use Versatility: These wipes are highly versatile and can be used across various industrial applications, including cleaning machinery, removing excess oil, degreasing parts, wiping down surfaces, cleaning hands, and even for polishing metal or glass surfaces.

Types of Industrial Wipes:

- Solvent-Based Wipes: Pre-moistened with industrial-grade solvents, these wipes are ideal for cleaning oils, greases, adhesives, and chemicals from machinery and equipment.

- Dry Wipes: For general cleaning and wiping, dry wipes can be used with a variety of cleaning solutions or on their own for dusting, wiping down surfaces, or cleaning hands.

- Wet Wipes: These wipes are pre-saturated with cleaning or disinfecting solutions, ideal for quick and convenient cleaning tasks. They can be used to clean up spills, sanitize surfaces, or wipe down tools and equipment.

- Microfiber Wipes: Known for their fine fibers, microfiber wipes are highly effective at capturing dirt, dust, and grease without the need for chemicals. They are used in precision cleaning, especially in the electronics and automotive industries.

Applications:

- Manufacturing and Production Facilities: Used to clean machinery, equipment, tools, and surfaces, preventing the buildup of dirt, grease, and chemicals that could affect performance.

- Automotive Industry: Perfect for wiping down engines, machinery, workstations, and cleaning hands after handling oils, grease, or automotive fluids.

- Construction Sites: Industrial wipes are used to clean tools, equipment, and work surfaces, helping to reduce dust and debris while keeping workers’ hands clean.

- Electronics and Semiconductor Industries: Non-linting wipes are ideal for cleaning delicate electronic components, preventing damage from dust, oils, and other contaminants.

- Food Processing and Hygiene: Wet wipes and solvent wipes can also be used in industries where hygiene is a priority, ensuring surfaces are kept clean without leaving harmful residues.

Storage and Usage Recommendations:

- Storage: Store industrial wipes in a cool, dry place, away from direct sunlight, to maintain their effectiveness and prevent premature drying out.

- Usage: Use the wipes as directed, especially when handling chemicals, solvents, or cleaners. For reusable wipes, ensure proper washing and maintenance as per the manufacturer’s instructions.

Kit Contents (if applicable):

- Wipes Roll or Pack: Typically available in rolls, pop-up boxes, or resealable packs, depending on the intended use and convenience. Rolls are often used for high-volume areas, while packs or boxes are more suitable for portable or workstation use.

- Dispenser (Optional): Some industrial wipes are packaged with a convenient dispenser, making it easy to access the wipes quickly and maintain an organized cleaning station.

Benefits:

- Increased Productivity: Industrial wipes help keep work environments clean and equipment functioning at peak efficiency, which can increase overall productivity and reduce downtime.

- Safety and Compliance: Regular cleaning with industrial wipes can help ensure that equipment and work areas meet health and safety standards, reducing the risk of accidents or contamination.

- Cost-Effective: Using high-quality industrial wipes can prevent the need for more expensive cleaning tools or frequent machine repairs caused by neglect.

Conclusion:

Industrial wipes are an indispensable tool for maintaining cleanliness, safety, and efficiency in industrial environments. Whether for heavy-duty cleaning, precision wiping, or everyday maintenance, these wipes are designed to meet the toughest challenges while providing excellent value for businesses across various industries.

Showing all 8 results

-

70 ipa wipes | Cleanroom Wiper Manufacturer

Read more -

Aerospace and Military Cleaning Wipes

Read more -

Alcohol Wipes For Electronics

Read more -

Antibacterial dust-free wipes

Read more -

Hitecloth optical lens cleaning cloth Kanebo

Read more -

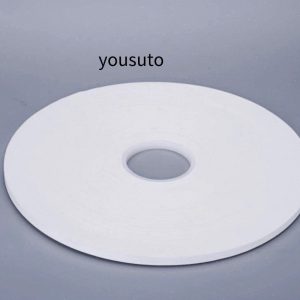

Microfine Roll Wipes Supplier | Microfine Roll Wipes Manufacturer

Read more -

Roll Wiping Wipes | Terminal Cleaning Roll Wiping Wipes

Read more -

ハイクロス 光学レンズクリーニングクロス カネボウ

Read more