ESD dust removal sticks are specifically designed for high-cleanliness environments (Class 10-100). They are made from highly clean, non-dusting, and low-ion content materials that do not contain allergens. These sticks offer excellent chemical corrosion resistance, and their anti-static treatment safely dissipates charges without being affected by environmental changes. They are suitable for cleaning and assembling electrostatic-sensitive products.

1. Applications:

- Excellent Adhesion: Ideal for cleaning micro-dust ions on exposed sensor surfaces in COB (Chip-on-Board) processes. Unlike ordinary cotton swabs (which use cleaning water on CSP sensor surface glass), these sticks do not produce dust points, do not scratch the sensor, and do not leave stains, significantly improving product yield.

- Particle Removal: Effective for removing particles from LED/LCD surfaces in Class 10-5000 cleanrooms and cleaning lens surface debris.

2. Features:

- Special Adhesive: Custom adhesive formulation, non-volatile, and non-shedding.

- Soft and Resilient: Provides good flexibility and operational feel. Environmentally friendly, non-irritating odor, and harmless to users.

- Protects Product: Offers excellent protection for both the electrical and physical appearance of the product.

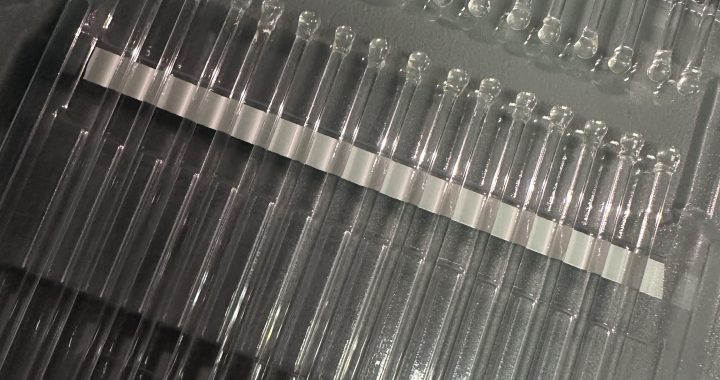

ESD dust removal sticks for Class 10-100 cleanrooms, made from ultra-clean, anti-static materials. Ideal for safely removing dust from sensors, LEDs, and LCDs without leaving residues or scratches

3. Operating Instructions:

- Packaging Removal: Remove the outer packaging and clean the dust removal stick’s outer packaging before entering the cleanroom through an air shower.

- Pre-Operation Preparation: Perform a 5S check (Sort, Set in order, Shine, Standardize, Sustain) on the work surface, floor, equipment, chairs, gloves, tools, fixtures, trays, etc., and inspect with a microscope.

- Handling: Use tweezers to gently pick up the stick from the tray. Avoid contact with objects to prevent contamination. Hold the other end with your hand and prepare for use.

- Usage: Align the stick with the dust spot under a microscope or software. Maintain a 60°-90° angle and gently apply the stick without excessive force to avoid scratching or damaging the sensor.

- Stability: Hold the stick steady, avoid shaking or moving it back and forth, and do not rub it on the product to prevent scratches.

- Frequency: Do not use the same stick to clean more than ten times to avoid secondary contamination.

- Post-Use: Keep used sticks away from the work area, separated from clean sticks.