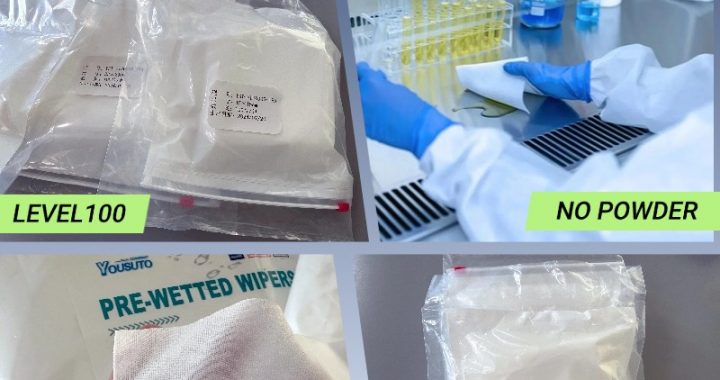

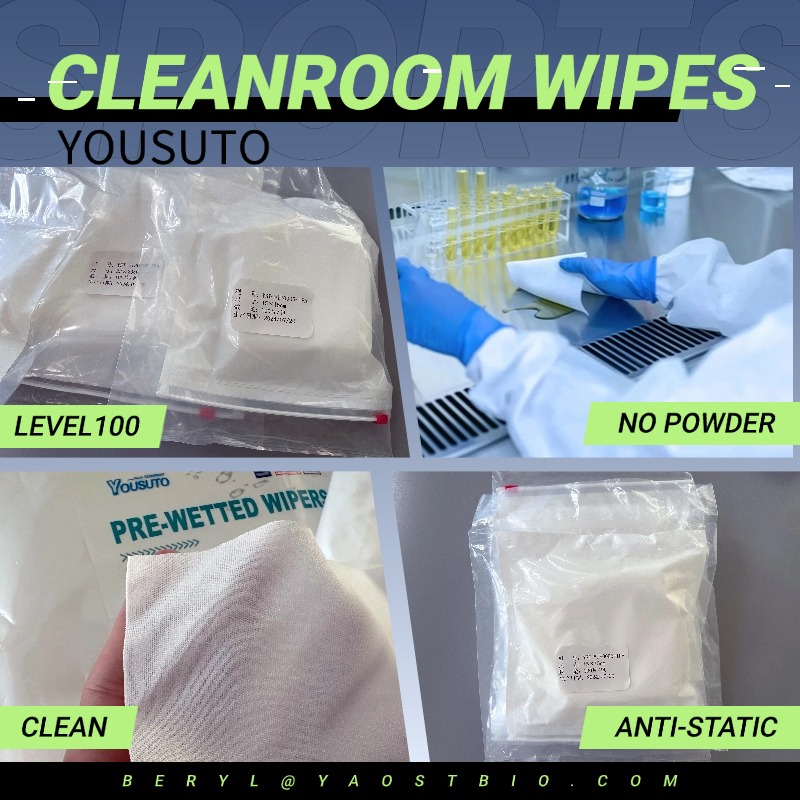

Pre-wetted cleanroom wipes are specially designed for use in highly sensitive and controlled environments. They are pre-saturated with a cleaning solution, making them an ideal choice for cleaning precision instruments. These wipes offer several advantages when compared to dry wipes, especially in maintaining the integrity of delicate surfaces and ensuring a thorough cleaning process.

Key Features:

-

Controlled Moisture Application: Pre-wetted wipes are already saturated with a carefully formulated solution, providing consistent moisture application. This prevents the overuse of liquids, reducing the risk of damage to sensitive instruments.

-

Effective Particle Removal: These wipes are designed to effectively capture and remove dust, oils, fingerprints, and other contaminants that may affect the accuracy or performance of precision instruments.

-

Lint-Free and Non-Abrasive: Pre-wetted cleanroom wipes are typically made from lint-free, non-abrasive materials. This ensures that no fibers are left behind after use, which is crucial for maintaining the cleanliness of sensitive optical lenses, calibration equipment, and other precision instruments.

-

Pre-Disinfecting: The cleaning solution used in these wipes often contains disinfecting agents like isopropyl alcohol, which not only cleans but also sanitizes surfaces, making them ideal for sterile environments.

Applications:

-

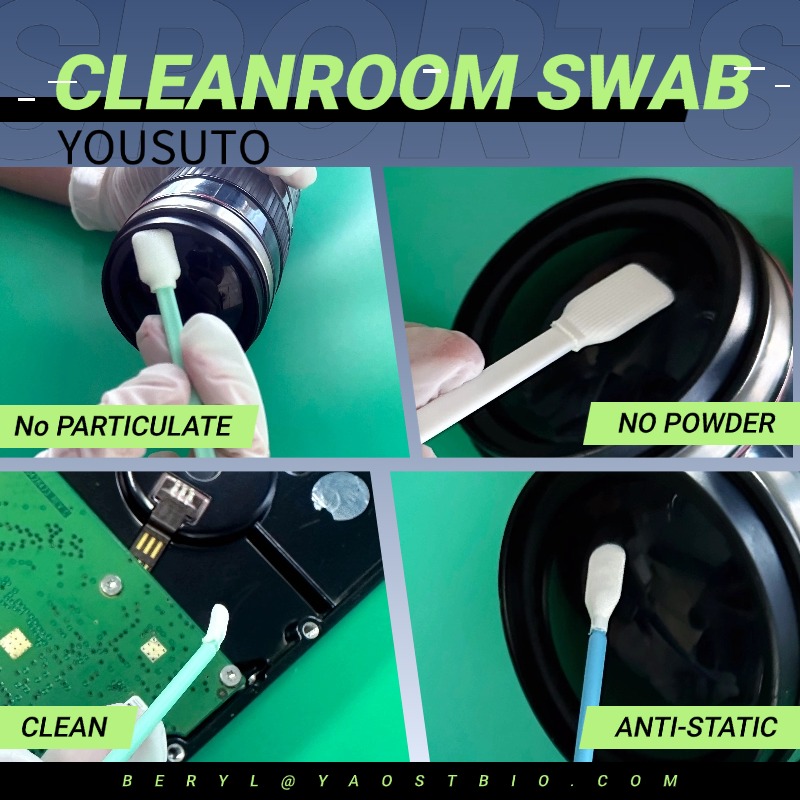

Optical Instruments: Used to clean sensitive lenses, mirrors, and optical sensors without leaving residues or damaging coatings.

-

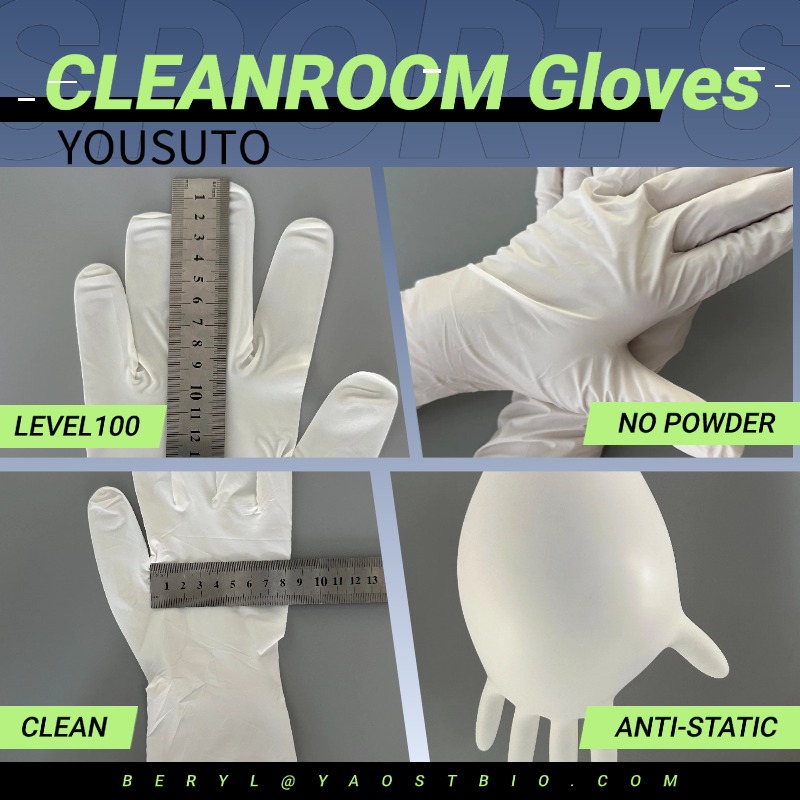

Precision Machinery: These wipes are ideal for cleaning the delicate parts of machinery and instruments in industries such as aerospace, semiconductor manufacturing, and medical device production.

-

Laboratories: Pre-wetted wipes help maintain cleanliness in laboratories, ensuring that microscopes, lab tools, and workstations remain free from contaminants.

-

Electronics and Semiconductors: These wipes are essential for cleaning delicate electronic components, such as PCBs and semiconductors, that require stringent cleanliness standards.

Benefits:

-

Reduced Risk of Contamination: By pre-saturating the wipes, there is a reduced chance of using excessive liquids, which can cause contamination in critical environments.

-

Enhanced Cleaning Efficiency: The pre-wetted design allows for faster cleaning, making it an efficient solution in high-demand settings where time is critical.

-

Preventing Damage: Lint-free and non-abrasive, these wipes prevent surface scratches and ensure sensitive instruments are cleaned without any risk of harm.