In IT cleaning, lint-free cotton swabs, lint-free wipes, and lint-free gloves are essential tools, especially when dealing with precision electronic devices and sensitive components. They effectively prevent contamination that could impact device performance due to residual particles or pollutants. Below is an overview of the specific applications and benefits of these tools in IT cleaning.

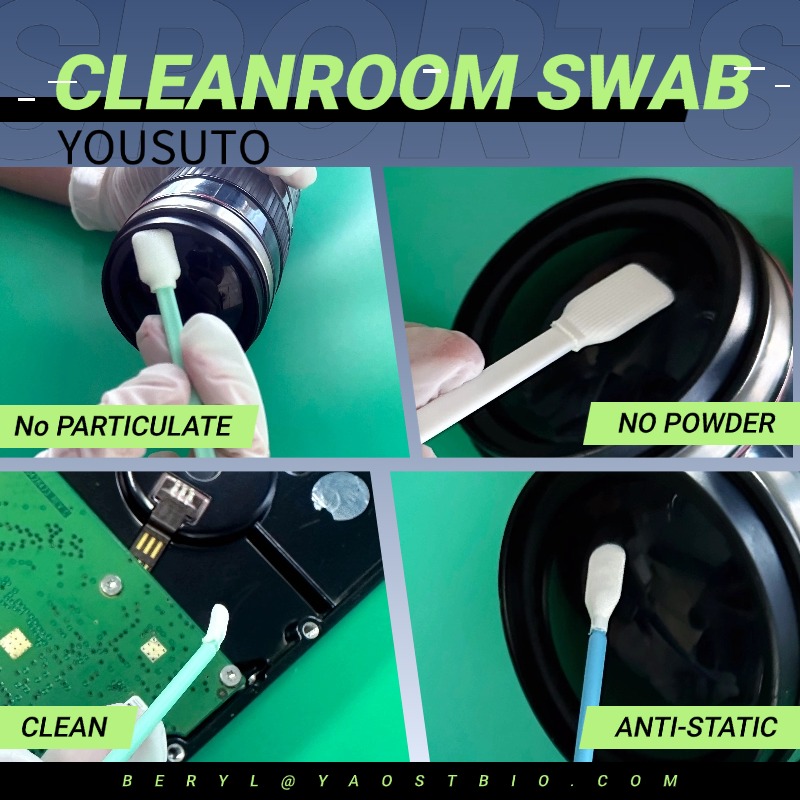

1. Applications of Lint-Free Cotton Swabs in IT Cleaning

Lint-free cotton swabs are primarily used for cleaning small components in IT equipment, especially hard-to-reach corners and connection points.

Application Scenarios:

- Cleaning Circuit Boards and Motherboards: Dust, oil, or other particles can accumulate on circuit boards. Lint-free cotton swabs can reach these tight spaces to clean without leaving residues.

- Cleaning Ports and Connectors: USB ports, HDMI ports, audio interfaces, and other connection points tend to collect dust and cause corrosion. Lint-free cotton swabs effectively clean these areas, ensuring no interference with signal transmission.

- Cleaning Displays and Touchscreens: Touchscreens and displays require careful cleaning, and lint-free cotton swabs can gently remove fingerprints, dust, and oil stains.

Benefits:

- Excellent Absorption: Lint-free cotton swabs effectively absorb dust, oil, and dirt, leaving no fibers or particles behind.

- Precise Cleaning: Their small size allows for detailed cleaning in hard-to-reach areas, making them ideal for intricate tasks.

CLEANROOMSWABS

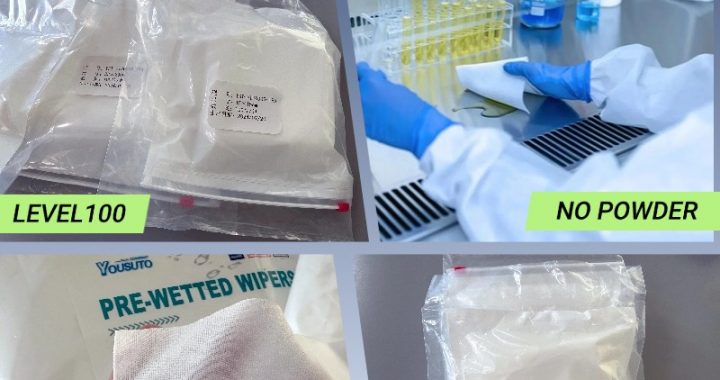

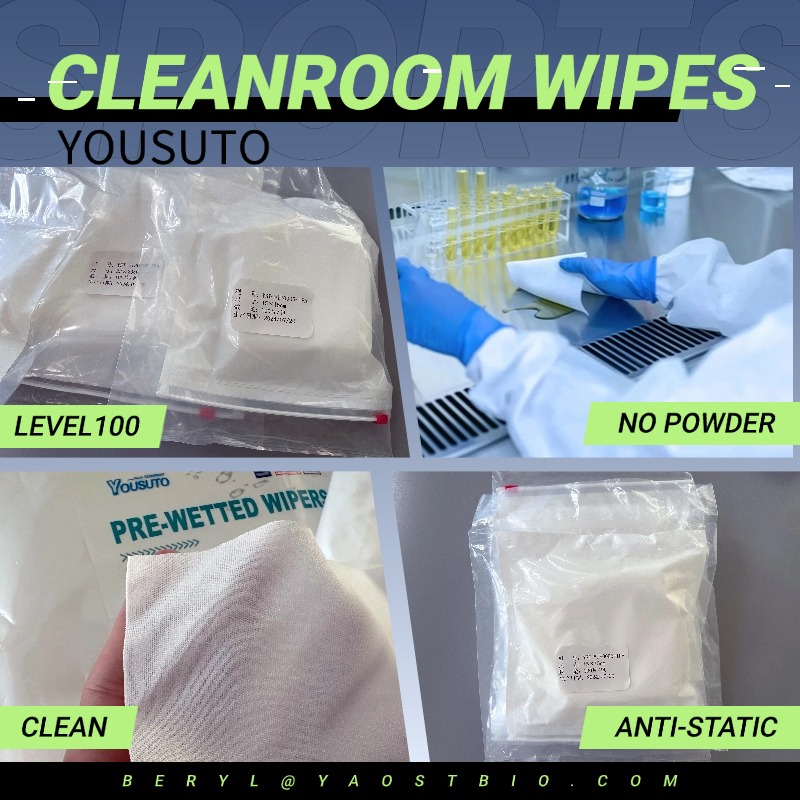

2. Applications of Lint-Free Wipes in IT Cleaning

Lint-free wipes are high-quality materials designed for cleanroom environments, typically used for wiping down device surfaces and cleaning larger areas.

Application Scenarios:

- Cleaning Displays: Lint-free wipes are ideal for cleaning computer monitors, TVs, touchscreens, and other screens, removing fingerprints, oil stains, and dust.

- Cleaning External Devices: These wipes can also be used to clean the surface of external devices like keyboards, mice, and printers, preventing dust and stains from affecting performance.

- Cleaning Casings and Surfaces: Lint-free wipes quickly remove dust and oil from casings, laptop shells, and server exteriors, keeping devices looking clean and free from contaminants.

Benefits:

- Low Particle Release: Lint-free wipes are designed to prevent shedding of dust or fibers, reducing contamination risks.

- Soft and Surface-Safe: These wipes are gentle on sensitive surfaces, preventing scratches or damage to the equipment.

CLEANROOMWIPES

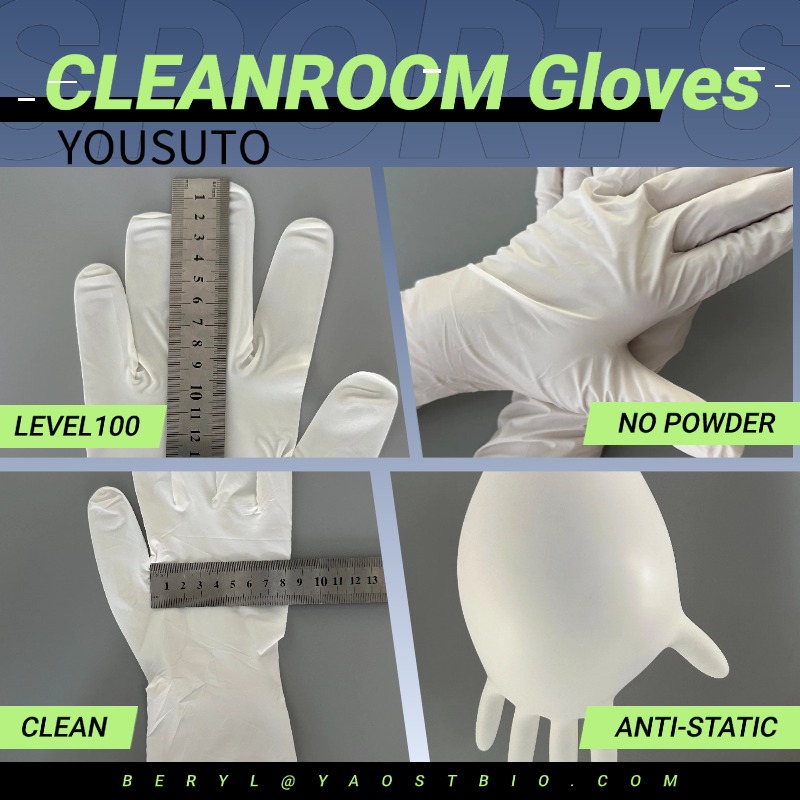

3. Applications of Lint-Free Gloves in IT Cleaning

Wearing lint-free gloves during IT cleaning is crucial, especially when handling small components, precision devices, or high-end electronics.

Application Scenarios:

- Handling Computer Hardware: When replacing hardware such as hard drives, graphics cards, or memory modules, lint-free gloves prevent oils, sweat, dust, and other contaminants from transferring to the device.

- Assembling or Repairing Computers: Lint-free gloves are essential during computer assembly or repairs to prevent electrostatic discharge (ESD) that could damage electronic components.

- Handling Precision Equipment: Lint-free gloves protect sensitive components like sensors or optical devices from contamination by dirt or oil.

Benefits:

- Prevent Contamination: Lint-free gloves help keep oils, dirt, and microorganisms from coming into contact with sensitive IT equipment.

- ESD Protection: Many lint-free gloves come with anti-static properties, protecting IT devices from static discharge damage.

- Comfortable Wear: The powder-free design ensures no residue or dust is left behind, making them comfortable for prolonged use.

CLEANROOMGLOVES

4. Integrated Use: The Combined Role of Lint-Free Cotton Swabs, Wipes, and Gloves in IT Cleaning

In comprehensive IT cleaning, lint-free cotton swabs, lint-free wipes, and lint-free gloves work together to achieve the best results:

- Step 1: Wear Lint-Free Gloves: Start by wearing lint-free gloves to prevent contamination from your hands—oil, sweat, or dust—during the cleaning process.

- Step 2: Use Lint-Free Wipes for Larger Surface Areas: Clean large areas, such as screens and external device casings, with lint-free wipes to remove dust and stains quickly.

- Step 3: Use Lint-Free Cotton Swabs for Small Components: Use cotton swabs to clean connectors, ports, circuit boards, or other small components to ensure no contaminants are left in hard-to-reach areas.