Video: Zebra Tabletop and Print Engine Printhead Cleaning Procedure

Cleaning The Zebra Printhead

Inconsistent print quality such as voids in the bar codes or graphics may indicate a dirty Printhead. For optimum performance, the printhead should be cleaned regularly. Zebra Technologies Corporation recommends performing the cleaning procedure when installing a new Roll of Ribbon or after 3 rolls of label stock.

Note: You are not required to turn off the printer power for this procedure. Remove all rings, watches, hanging necklaces, identification badges, or other jewelry that could touch the print head or get caught in the printer. If you turn off the power, you will lose all temporary settings, such as label formats, and you must reload them before you resume printing.

Click here for information on extending the life of your printhead.

.

Zebra Tabletop and Print Engine Printhead Cleaning Procedure

Printhead Cleaning Procedure:

1. Open the Printhead by moving the Printhead Lever to the OPEN position.

2. Remove the media and ribbon (if present).

3. Use a cleaning swab (99.7% isopropyl alcohol) and wipe the print elements from end to end. (The print elements are the grayish/ black strip just behind the chrome strip on the underside of the Printhead.) Allow a few seconds for the solvent to evaporate.

4. Rotate the Platen Roller and clean thoroughly with a cleaning swab.

5. Brush or vacuum any accumulated paper lint and dust away from the Rollers

and the Media and Ribbon Sensors.

6. Reload ribbon and/ or media, close and latch the Printhead, restore power

(if necessary) and run the PAUSE Key self test to check print quality.

Click here for Pens and Kits information

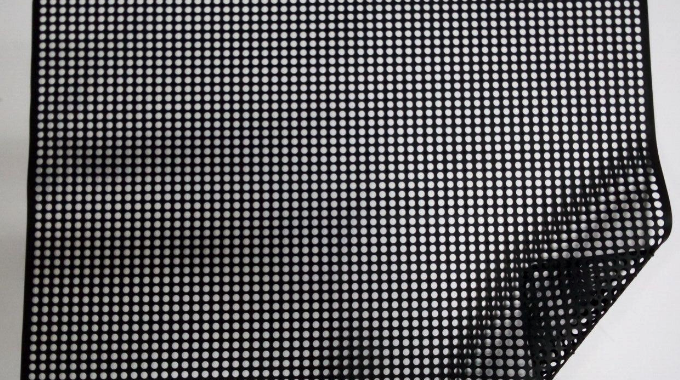

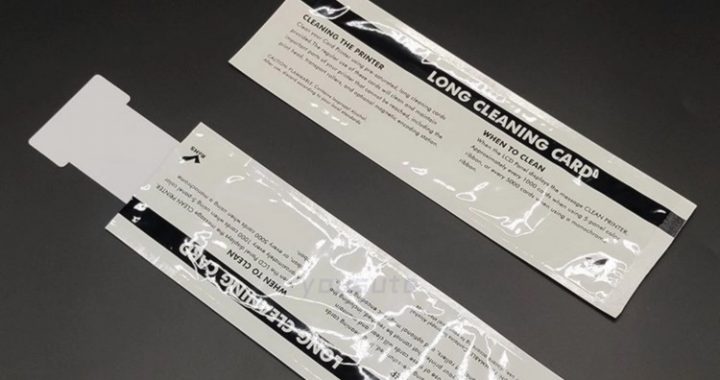

Note: Silverline RFID printer printheads must only be cleaned using Save-A-Printhead Cleaning Film shown below.

Helpful Information

Extending the life of your printhead Read More>>

Tough or hardened printhead buildup can be removed using “Save A Printhead” Cleaning Strips Read More>>

Part Numbers for Save-A-Printhead Cleaning Film Kits. Order kit number: For Printers with Print Widths:

- 46902 3.0″ – 4.0″ (76 mm–102 mm)

- 44902 4.0″ – 5.0″ (102 mm – 127 mm)

- 48902 5.0″ – 6.0″ (127 mm – 152 mm)

- 38902 6.0″ – 7.0″ (152 mm – 178 mm)

- 22902 8.0″ – 9.0″ (178 mm – 229 mm)