High-density antistatic cleanroom wipes are essential tools for maintaining cleanliness and preventing electrostatic discharge (ESD) in sensitive environments like cleanrooms, laboratories, and electronics manufacturing. When choosing these wipes, several factors should be considered to ensure they meet specific cleaning and safety requirements.

Key Features:

-

Antistatic Properties: High-density cleanroom wipes are specifically designed to dissipate static charges, preventing electrostatic discharge (ESD) that could potentially damage sensitive electronic components, such as semiconductors and circuit boards.

-

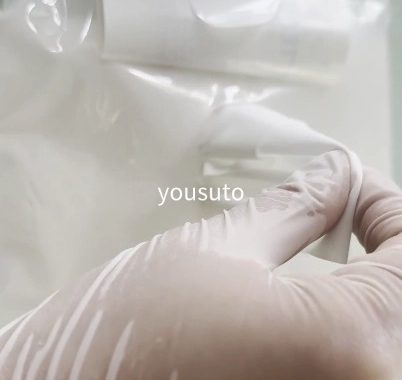

High-Density Fabric: These wipes feature tightly woven fibers, allowing them to capture and retain dust, particles, and liquids more effectively than standard wipes. This high-density structure also helps reduce the risk of lint or fiber shedding, making them perfect for high-precision cleaning.

-

Lint-Free and Non-Abrasive: The wipes are manufactured to be lint-free and non-abrasive, ensuring no fibers or particles are left behind on cleaned surfaces. This is essential when cleaning delicate surfaces or sensitive equipment in cleanroom settings.

-

Chemical and Solvent Resistance: High-density wipes are durable enough to handle various cleaning solvents, including isopropyl alcohol, acetone, and other industrial cleaning agents. They remain intact without degrading, ensuring consistent performance during extended cleaning tasks.

Key Purchasing Considerations:

-

Cleanroom Classification: Ensure the wipes are suitable for the cleanroom environment you’re working in (e.g., Class 100, Class 1000). Different environments may require wipes with varying particle retention capabilities and static control properties.

-

Wipe Size and Packaging: Consider the appropriate wipe size for your application (e.g., 4×4 inches, 6×6 inches) and the packaging quantity based on the volume of cleaning required. Larger wipes or bulk packs may be more cost-effective for high-use environments.

-

Absorbency: Check the absorbency rate of the wipes. High-density wipes should be able to absorb liquids effectively, which is especially important in environments where solvents or chemicals are used during cleaning.

-

Compatibility with Equipment: Make sure the wipes are compatible with the surfaces and equipment being cleaned. For sensitive electronics and optics, choose wipes that are non-abrasive and free from contaminants that could harm delicate devices.

Applications:

-

Semiconductor Manufacturing: Used to clean wafers, circuit boards, and other delicate electronic components, ensuring no static or particulate contamination.

-

Pharmaceutical Manufacturing: Helps maintain sterile environments by cleaning surfaces without leaving residues or fibers that could affect product quality.

-

Precision Electronics: Essential for cleaning high-precision instruments, optical devices, and medical equipment, where even the smallest contaminant can cause malfunction.

-

Cleanrooms and Laboratories: Ideal for general cleaning in controlled environments, helping maintain strict cleanliness and ESD control standards.

Benefits:

-

Reduced ESD Risk: Antistatic properties protect sensitive equipment from electrostatic discharge, reducing potential damage.

-

Improved Cleaning Efficiency: High-density design captures more contaminants, resulting in a cleaner environment and more effective cleaning.

-

Long-Term Durability: Resistant to chemicals and solvents, these wipes offer long-lasting performance in harsh cleaning conditions.