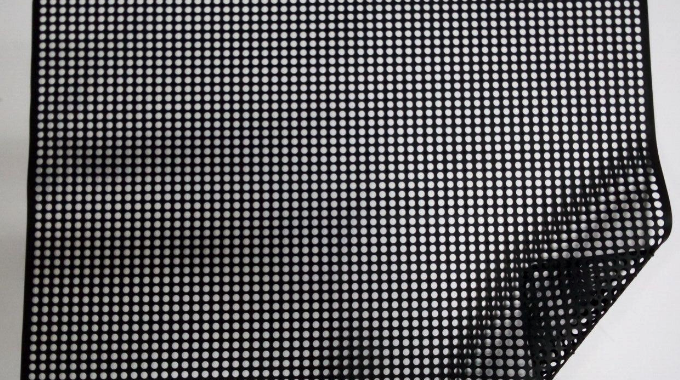

In industries such as electronics manufacturing, mobile phone assembly, and optical glass, product safety and quality are paramount. The anti-static silicone non-slip mat is an essential tool that effectively prevents products from slipping, absorbs vibrations, and protects sensitive electronic devices. It is particularly suitable for products with LCD screens, mobile phone covers, optical glass, backlight modules, CD glass, and more.

1. Prevents Slippage, Ensures Product Safety

One of the main functions of the anti-static silicone non-slip mat is to prevent products from slipping during operation or storage. With its excellent surface friction, it firmly holds products in place, reducing the chances of movement. This is especially critical in environments that require high precision, such as mobile phone assembly lines or optical glass manufacturing workshops.

2. Vibration Resistance, Reducing Damage Risk

Silicone material has superior vibration resistance. This feature is crucial because it minimizes the risk of damage to products during transport or handling. For fragile items like LCD screens, mobile phone covers, and optical glass, vibration protection significantly reduces the chances of product breakage or failure during production or shipping.

3. High-temperature Resistance, Suitable for Various Environments

This non-slip mat boasts excellent high-temperature resistance, withstanding temperatures up to 200°C. Whether during high-temperature soldering of electronic components or other heat-intensive processes, the anti-static silicone non-slip mat remains stable and provides reliable protection.

4. Soft Material, Protecting Precision Equipment

In addition to being non-slip and heat-resistant, the silicone material is soft, effectively preventing scratches and bumps. This is especially important for precision components like mobile phone covers and optical glass. The softness of the silicone mat ensures that it won’t cause additional friction or damage when in contact with devices, maximizing surface protection.

5. Anti-static Function, Protecting Electronic Components

The anti-static silicone non-slip mat also has excellent anti-static properties, with a surface resistance of 10^6 to 10^9 ohms. This effectively prevents static buildup, protecting sensitive electronic devices from static damage. This is particularly important for products with LCD screens and mobile phone modules that contain electronic components, as static protection reduces the risk of damage and performance degradation.

6. Washable and Reusable, Environmentally Friendly and Durable

Not only is this silicone non-slip mat highly functional, but it is also easy to clean and reusable, offering excellent durability and environmental benefits. After cleaning, it can continue to be used without compromising its non-slip or anti-static properties, reducing operational costs for businesses while contributing to environmental sustainability.

7. Wide Range of Applications

The anti-static silicone non-slip mat is widely used in various industries, including mobile phone production, optical glass manufacturing, LCD assembly, and backlight module assembly. Whether on mobile phone module production lines, optical glass cutting workshops, or backlight testing environments, this mat plays a crucial role.